In the contemporary food industry, maintaining the hygiene and operational efficiency of processes centred around coffee powder is a critical area of concern. Industry experts believe the global consumption of coffee continues to rise at unprecedented rates. Manufacturers are under increasing pressure to maintain product quality and shelf-life while simultaneously increasing productivity. This has spawned ever-more-convoluted coffee powder packaging machines that maximize product safety without sacrificing operational efficiency. It is important to grasp the variety of coffee powder packaging machines available so as to make the right technology choice for your production line.

Need to Maintain Freshness and Aroma in Coffee Powder Packaging

Freshness and aroma are two volatile properties of coffee that are highly coveted, hence their importance in marketing. Freshly ground coffee may release soft, aromatic nuances as long as it remains sealed, however, exposing it to air, moisture, and light will drastically quicken the speed at which it starts losing g aromatic qualities. Modern coffee powder packaging machines often come equipped with vacuum-sealing, nitrogen-flushing, and one-way degassing valves which guarantee the preservation of the evaporating substances that give the coffee its essence.

The removal of oxygen or its replacement with inert gases in the above machines reduces the oxidation process which makes coffee stale. In terms of freshly ground coffee, the release of gas is very critical and is best handled by the so-called degassing valves that prevent air from getting back inside the container, thus allowing carbon dioxide to escape freely. The goodness of coffee scent is preserved while preventing the coffee from swelling and bloating. In addition, advanced sealing systems provide airtight protection of the container with the use of impulse, band or ultrasonic sealing. With these technologies, consumers can enjoy brewing coffee that tastes like it has just been packed.

Exploring the Types of Packaging Machines for Coffee Powder

Not all machines are suitable. It all starts with the knowledge about various coffee packaging machines and their specific work requirements. Coffee powder has numerous solutions and one of them is vertical form fill seal (VFFS), which is perfect for high speed and bulk production. With VFFS machines, coffee powder is filled into pouches created to meet the required dimensions unlike other pouch filling machines. So the machines create the bag from roll stock film, fill the pouch with coffee powder using rotary auger fillers and seal it all in one motion. In industrial environments, inline VFFS machines are widely used because of their speed.

Pouch filling machines offer specialty coffee producers a greater degree of flexibility compared to their competitors. These machines are capable of handling a variety of pouch styles, such as flat pouches, stand-up pouches, and gusseted bags, often with added features such as resealable zippers or custom imprinting. While vacuum sealing machines tend to be slower, they offer maximum protection by removing all air from the package, making them ideal for premium coffee lines. Each of these machine types offers distinct benefits, and choosing the right option comes down to production volume, product attributes, packaging design, and brand identity.

Due to the diverse consumer preferences, many companies invest in multifunctional tools that accommodate different styles of packaging. A coffee powder packaging machine that supports multiple types of packaging machines in a complete line is more flexible and protects the production process from changing market needs.

Achieving Efficiency with Automation and Smart Integration

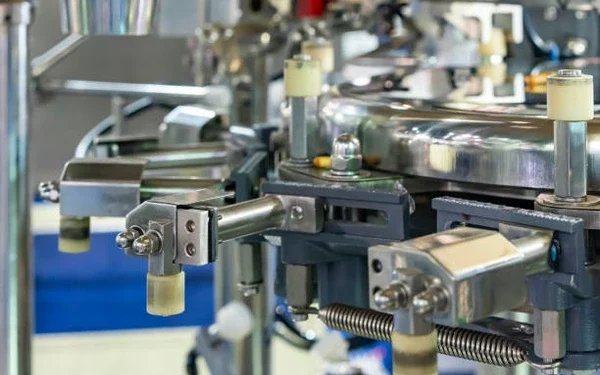

In every business, maintaining operational efficiency is key to long-term success even alongside preserving quality. Modern coffee powder packaging machines now offer full automation which minimizes manual participation and enhances consistency across production batches. Manufacturers can achieve their productivity targets with automated real-time performance monitoring, PLC control panels, and servo-driven auger fillers while sustaining low operational waste. These systems significantly enhance productivity by offering remote diagnostics, precise recipe management, and efficient changeover which reduces downtime.

Filling accuracy, sealing precision, and professional labeling of each package is guaranteed with the automated integration of the grinders and filling units, the sealing, and the labeling modules which streamlines the processes from bean to the final product. Some of these systems are equipped with IoT connectivity features which truly elevate the entire workflow by enabling predictive maintenance and data-driven optimization of the entire packaging workflow while increasing product traceability and eliminating manual intervention.

Whether a manufacturer is processing bulk orders or running small, boutique batches, the benefits of automation are concise. Some advantages include increased speed and lowered wage expenditures, improved hygiene, and adaptability in real-time. Additionally, integrating smart packaging systems improves efficiency. With proper employee training and maintenance schedules, these machines, along with smart packaging systems, can provide reliable support for a high-output coffee production line.

Read Also: 6 Emerging Trends Shaping Contract Lifecycle Management

Sustainability and Market Trends in Coffee Packaging

Besides the protective function of packaging, sustainability has become an increasingly important concern nowadays. In response, coffee brands are adopting more compostable materials, recyclable films, along with minimalistic designed packaging. This expanding trend alongside the rise in eco-friendly materials has given coffee packaging machine producers the purpose to invent new reliable machinery that works with easily-damaged eco-friendly substrates. Materials like traditional plastic laminate and other forms of flimsy bioplastic film are being replaced by sustainably sourced paper and bioplastic film. These eco-friendly alternatives have different durability, sealing, and temperature control requirements, so customized settings need to be applied including variable heat parameters which require precision.

Moreover, coffee packaging machines have an ever growing challenge of maintaining aisle life protection alongside sustainability, which is achieved through more adaptive sealing technologies. Furthermore, eco-conscious packaging must also remain visually appealing alongside the need to easily mitigate and retain labels. Other portion-control sachets as well as mono-materials which are less complex for recycling are used, which enhances functionality without needing to sacrifice aesthetics.

The agility of the machine is, therefore, of utmost importance. Manufacturers who aim to switch to more environmentally friendly materials require machines that can be configured easily, deal with changeover wastes efficiently, and are compatible with newer materials. As the shifts in regulations concerning plastic waste and general concerns for the environment increase, the capability of packaging machinery to contain eco-friendly formats and sustain rapid production or secure enclosement will play a pivotal role in determining the equipment’s brand value, participation in industry and competitive advantage.

Conclusion

Achieving a competitive coffee market balance for freshness, aroma, and operational efficiency is a challenge. Thankfully, the technological advancement of today’s coffee powder packaging machine has made it easier to consistently produce top-quality products in large quantities. An understanding of the different types of packaging machines permits manufacturers to refine their choices regarding brand identity, production scales, and customer expectations. If sealing in the delightful scent of a premium roast or fulfilling a high-volume market is the objective, the world of coffee demands an industry-leading packaging machine.